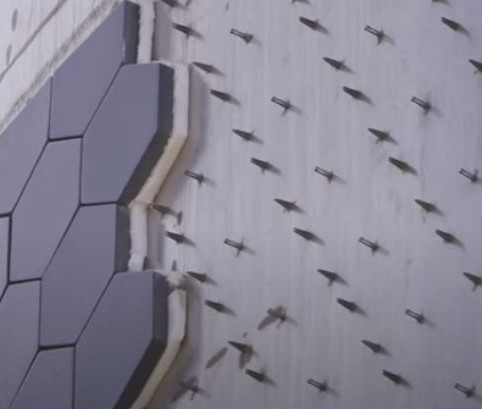

Recently, a SpaceX Starship ran into a setback that’s been ongoing for a couple of years now – tile popping off. We get to see all this, as SpaceX runs a very open program, much of Starship taking place in the sights of a paparazzi of cameras and drones. We see that sticking protective tile on a spaceship is no trivial matter. Nor is this your parent’s Space Shuttle or tiles. Then again, the Space Shuttle’s iconic black tiles are too often over-simplified – they are a system of silicone adhesive, felt pads to allow movement, then tile. Even the better figures here neglect to show more, like the adjacent gap fillers, preventing tiles from chattering and chipping against each other. The Shuttle flexed with the tremendous forces of launch, flight, and re-entry from orbit. For Starship, all the tiles will want to accommodate all that flex too, and worse.

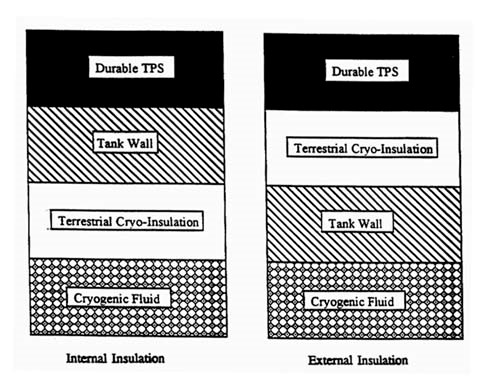

A Starship takes Shuttle tile technology much further, placing them not atop an aluminum Shuttle structure, primed, green and clean, but rather atop a layer of insulation. Starships have their cold propellant inside them, not in a big orange External Tank like the Shuttles. This difference might sound trivial to anyone who ever put up some tile in a shower. But, except now for Starship, you might consider how you would stick tile directly onto that bathroom wall’s insulation, minus the concrete backer board in-between.

Long ago, NASA must have figured out this tile-on insulation nightmare. Right?

An interested observer might wonder just what NASA did with all that research into reusable launch technology – billions of dollars’ worth over decades. Long ago, NASA must have figured out this tile-on insulation nightmare. Right? Oddly, the most telling public figure about how this *might* work is worse than the oversimplified figures of Space Shuttle tiles. A little googling for more in the public record won’t hit the jackpot anytime soon. This leads to the question – is figuring out tile direct on cryogenic insulation a real technical challenge, or is something else going on?

Kennedy Space Center in 1988 was a world of fantastic technology but not so incredible paper. Paper was everywhere. Paper filled our shelves, walls of cabinets, boxes under desks, and precariously asking for a fine from OSHA, boxes atop cabinets. And then there were the cabinets with combination locks. These held some sensitive information (/s) in the days when Soviet (Russian) trawlers awaited our launches off-shore with bated breath just like the tourists. (Our secretary held the combination. Often, the room for these cabinets went unlocked after hours. Go figure.) But to really impress, Kennedy maintained a “secure” room in the Launch Control Center. Security de-bugged the room before any meeting, and the single phone line (right to Commissioner Gordon?) was supposedly super-secure (so we were told.) This was everyone’s introduction to our duty to guard knowledge, loose lips, sinking ships, and all that.

But if our knowledge loop felt constipated, technical or funding difficulties only partly deserved blame.

Yet the cabinets or a secure room paled in comparison to the vault. Cabinets with combination locks and debugged meeting rooms came and went. We moved on, or the budget got cut, someone said. Yet well after 2000, this vault remained. Reading certain “Secret” material from the US DOD meant getting a hard copy delivered to this secure KSC room. Inside this government beige room, with too many coats of glossy paint, sat this large green bank vault. A little old lady managed access. She could be perfectly cast in a Quentin Tarantino version of a Mission Impossible movie. You could not take anything in or out of this room. I learned jokes here did not elicit a smile. I confirmed what I had already heard about DOD documents and over-classification.

Unsurprisingly, some technology needed work or progress meant a full-scale test next. All this was public knowledge. But if our knowledge loop felt constipated, technical or funding difficulties only partly deserved blame.

Tile for a reusable spaceship with propellant tanks inside may have a long way to go. It is a system of tile, cryogenic insulation, fastening, or adhesives, with separation, height, and transition requirements. The holy grail, true reusability, will mean staying well below a max temperature. If even one return gets an area too hot, there are margins to spare, but that section will not be rated to fly again.

By 1999, the Space Shuttles thermal protection system was out there, documented in detail, and shared for all to see. Our next-generation systems – not so much. This is a reminder that if true launch vehicle reusability is a holy grail, reusing knowledge is also a challenge. Intellectual property and plain old competition explain why knowledge doesn’t flow across companies. Regulations and caution explain other blockades, from the government to the private sector. And yet, time does overcome barriers, as Starliners or Dragon spacecraft re-learned most everything about thermal protection systems, and then some. Inevitably, we will figure out the technical barriers to launch reusability, sooner perhaps versus later. But it may be that knowledge that’s reusable will take a bit longer.