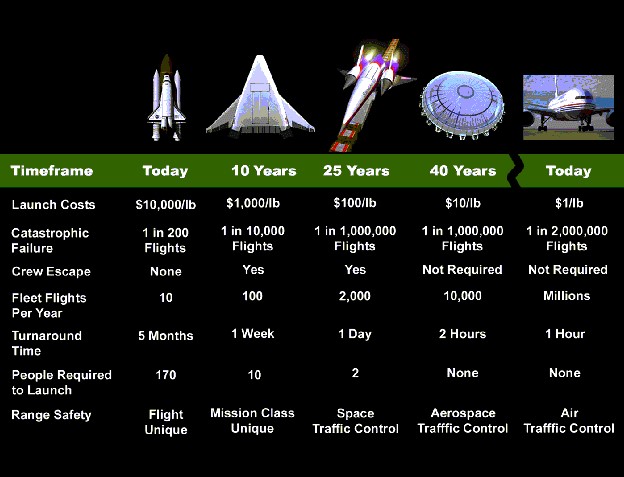

The room filled with the usual suspects and small talk. This year, it seemed an unwritten rule that before any presenter could talk about their good work there came this particular chart. It was the late 1990s, exciting times when ever-faster computers, internet connections, and aerospace technology came together to spur dreams of things to come. This chart was part of that. The future was simple, or so it seemed, a series of steps from today and getting something to Earth orbit costing $10,000 a pound to a fully reusable launcher costing just $1,000 a pound, and so on down the road. In a generation, we will fly in machines that are merely 100 times more expensive than hopping aboard a flight to Atlanta. As expensive as that might seem, it would be worlds cheaper than where we were.

It was not quite so simple. The X-33 and next-generation air-breathing vehicles launched from magnetic levitation catapults came and went among many technologies and systems NASA invested in. All the parts and pieces of hardware and studies never ended as flying machines. The costs would not drop just then, not yet, nor the prices atop those costs. At the time, though, the lack of certainty on dropping the price of getting to space did not keep people from jumping to what they might pack as luggage once cheap rides became available. This unique relationship between the ride to space and what goes inside the ride persists to this day.

One of the ideas back in the late 1990s for what might be the luggage for cheaper rides was Space Solar Power (SSP, or later ‘SBSP’ after a 2007 DOD study changed the name), a rebirth of an idea going back many decades. John Mankins at NASA Headquarters Office of Advanced Concepts and Technology was the champion for this idea. If NASA investments were to make getting to space cheaper, it would follow that the rides at these lower prices would also be increasingly for other than NASA and government agencies. Power stations in space were a natural next step.

Here in sunny Florida, a homeowner might get 5 to 6 hours a day of wonderful sunlight for their solar panels, but much less on each side of that time as the sun rises and sets or when the weather is poor. Space Solar Power imagined a sun that never sets. Solar panels placed in orbit would always face the sun and transmit power to Earth 24 hours a day, all year. This was not just a redirection of light. Instead, the power stations in space would transmit the power they received from sunlight to Earth after converting it to microwaves. These were heady times when all this and more seemed possible. The power stations were massive, so they needed the transport cost to get down to that mere $100 a pound.

The vehicles, however, were not quite massive, but SSP would make up for that with a high launch rate. If a launch a week would make for exciting times, the need here was for launches per day. On this side of the equation, a team at NASA Kennedy Space Center (myself included) was recruited to run the numbers. How many launches a day was possible given these technologies (if they became real)? Were the vehicle designs arguably consistent with launches per day? On what vehicles might this happen best, out of the assortment that seemed to grow daily, from pure rockets to airbreathers, from larger to smaller, or single to two-stage, but always reusable to be sustainable.

Mankins saw another link beyond just a commercial opportunity and a world hungry for power: a demand to attach to a supply of vehicles. This was about more than just NASA moving toward being “one of many customers” for a ride (a phrase that did not become routine till decades later). Climate change was here and now, and what could NASA do about it?

The room had amphitheater seating, and the lights were dimmed during presentations. At our turn, we had done our best to show how multiple launches a day were possible, to show the promise of how the far-away and impossible could be near and not so far-fetched. That is, if the designs from the vehicle teams had certain qualities (all big “ifs”), technology advanced and mature and robust beyond anything at the time, meaning launch rates and prices to build massive solar power stations in space were possible. These would be affordable, operable launch vehicles, close cousins to the airliners that opened air travel to the general public, rather than just the rich or the subsidized snail mail. For all the good work, though, it was here in this dim setting as presenter after presenter chimed in that it dawned on me and others that all this was not enough. The dim setting was appropriate to the epiphany.

The real problem was the demand for power on Earth grew faster than we could throw power towers in space at it. Even if what we could build made us look like an advanced alien race in its infrastructure heyday, it was far from what was needed. When I turn to Mankins, though, he is not surprised. Perhaps he already sensed the outcome. Adding up more detailed and better numbers across many experts and teams had not fundamentally changed the range on any of them from the start. Yet somehow, this philosophical resignation was matched by a desire to push on that persists today. Further progress would make the entire range move, eventually closing in on the target and adding up to power from space as fast as needed.

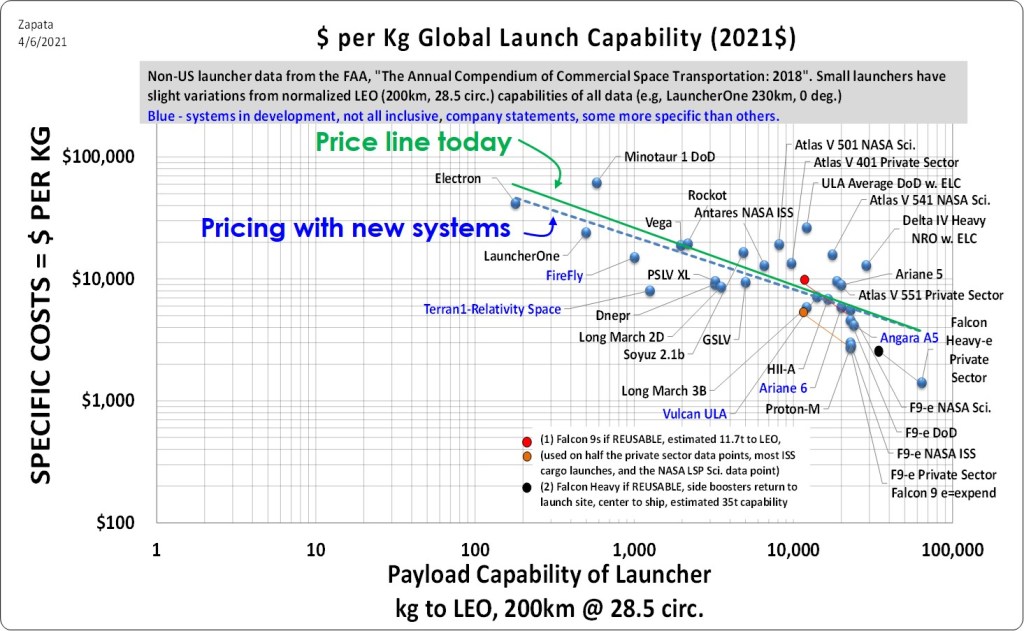

At the time, the numbers were staring at us all. Earth needs power, and even putting a massive solar power tower in space every year with thousands of tons of mass did not add up to keeping up with the growing power demand on Earth. For perspective, the most capable semi-reusable launch vehicle today, the Falcon Heavy, can put up about 35 tons at a time if its side boosters return to the launch site and its center booster lands on a drone ship at sea. Even if it might add up on launch frequency, that 35 tons today is still too expensive, as much headway as it’s made to lower costs from where we were.

Of course, we could see a day when, with just more launches and lower prices, the power towers in space could keep up with Earthly demand for abundant, clean energy. The space tower technology could also get less expensive with time and more innovations like modules to ease manufacture on Earth. There would be experiments on Earth transmitting power across distances, such as the work of Nobuyuki Kaya in Japan. More recently, Paul Jaffe at the Naval Research Lab has focused on well-defined applications like military scenarios providing power to far-off outposts to reduce fuel convoys along dangerous supply lines. All of this boils down to that measure – the cost per pound (or kilogram). There is no lack of keeping track of this metric in the industry, not just for making concepts like space solar power possible but for a world of such concepts also waiting for their day in the sun.

Refueling, private stations, and more

In the decades since we envisioned what might be for SSP, there has been no lack of more construction ideas and travel destinations waiting in line for low fares. Pondering a cost per pound, an obvious question became a pound of what? It turns out most of what might end up in orbit to go anywhere beyond is just propellant. By 2011, a team at NASA was looking at refueling in space. Once again, as with SSP, if the fare for the ride was much lower to get to orbit, a distinct possibility from seeing where the SpaceX Falcon 9 was going, what might be possible with the Falcon Heavy on the drawing board? That task was undertaken by Charles Miller, NASA’s Senior Advisor for Commercial Space at the time, who ran with the possibilities. Many launch vehicles could compete to launch lighter, near-empty spaceship stages, while others competed to load them up with propellant once in orbit. All this would make enormous sense at the lower prices per pound to low Earth orbit versus trying to get the mass up there all at once in any larger, more unique, less flown, and much more expensive launcher.

Miller and his team would report on this (myself again included) – only not everyone was convinced. Some would argue that refueling in space was immature, and in either case, Congress had already tasked NASA to build a giant rocket that could put up a large mass, propellant, and payload, all at once. The task did not end well for the team. The numbers favoring refueling were compelling then, and they remain so, but the timing for such change was off.

Persisting, 2015 offered a repeat performance. Now Miller was outside NASA leading an independent look, skipping the stop at a gas station in space, now with “tanker” stages directly off-loading propellant to the customer. Here, the gas station would come to you. The Evolvable Lunar Architecture study also included commercial lunar landers, perhaps two, perhaps one. All this would lead in phases to fully reusable landers refueling on the Moon from propellants mined and produced there. Using partnerships and going commercial, it would all add up if the promising recent history for this NASA investment approach were repeated. There could be a permanent and growing presence on the Moon much sooner and for much less NASA budget than anything envisioned.

The evolvable lunar architecture didn’t need to de-orbit the ISS to free up funds to go to the Moon – a practical strength to the plan. The supply chain was strengthened along the way to the Moon rather than abandoning your rear at Earth orbit under the guise of limited resources. To Miller, it was “about a propellant economy in space,” but not everyone got it. Again, the numbers were compelling and remain so, but the timing for such change was off. Only now, by not as much.

Fast forward to the middle of a global pandemic and awaken in 2021. Anyone who predicted such change would be accused of wishful thinking. In April, NASA’s Perseverance rover has extracted oxygen on Mars. From the barely-there carbon-dioxide atmosphere, a small device called MOXIE has yanked out the oxygen and tossed aside the carbon in a process that might one day lead to refilling a ship on Mars with liquid oxygen. For refueling in space, NASA has awarded a contract to Eta Space to develop technology for transferring liquid oxygen. And atop all this, NASA has partnered with SpaceX to transfer 10 tons of liquid oxygen in Earth orbit. If all this sounds eerily again like waiting for low fares for that otherwise unaffordable trip, it is. Except the low fares no longer seem far away. Forgotten in this, liquid oxygen is liquid oxygen, and liquid methane is liquid methane, even if everyone’s stages and what’s packed atop those remain unique and less amenable to becoming commodities. The propellant remains most of the mass of getting anywhere, ready to take advantage of low costs per pound to orbit.

Also, all the refueling in orbit is now seriously back on the NASA table after a touch-and-go moment in early 2020, where NASA went commercial after all for its lunar lander. NASA’s eventual commercial lander selection (pending a final outcome on challenges from the losing bidders) was a reusable approach – the SpaceX Starship. The timing for refueling, reusable landers, and landers as partnerships for future commercial services was no longer off. The day had come.

The list goes on for what’s possible and the people who see the opportunities. As costs per pound drop, the commercialization of low Earth orbit is now on the table. This is also about more than just the launcher, as getting to low Earth orbit, as the saying goes, is halfway to anywhere in the solar system. It is no coincidence that a private mission to space will soon use the Dragon spacecraft developed for NASA crew trips to the International Space Station. The Inspiration4 mission – “four crew members representing the mission pillars of leadership, hope, generosity and prosperity” – would arguably not be going to space were it not for a vehicle and a spacecraft the reliability, safety, and price of which allow such a private mission. It helps that these are not government-owned or operated. Manufacturing can see a similar renaissance – as NASA’s Lynn Harper, lead of integrative studies for the Space Portal Partnerships Office at NASA, is fond of saying – as we discover “where gravity is holding back US industry.” Perhaps the breakthrough app for something made in space will be ultra-pure optical cable, ZBLAN at $2 million a kg, or a crystal used for a cancer drug (like Keytruda). It could as likely be something unexpected, more valuable than we can guess.

Refueling, the commercialization of low Earth orbit, from private space stations, for tourism, manufacturing, science, and research, helping us live longer, healthier lives, and yes, perhaps one day for space solar power is merely what we can imagine. The old “build it, and they will come” model may have been unambitious. In an era of thousands of Starlink satellites in orbit, what else might be on the table? Months ago, I had the rare opportunity to catch a recently launched fleet of Starlink satellites pass over the sky here in Orlando. A tidy row of bright lights streaming by on a clear evening from horizon to horizon leaves an impression. I wonder who might have dreamed a new dream on such an evening. For perspective, a completed Starlink constellation is of a mass of a multi-gigawatt Space Solar Power station – and it’s not waiting around for even lower costs on the ride and more often. This could all be a fantastic picture of systems to get to space and systems and people in space that make the old NASA chart, with X-33, Maglev, and the laser-craft, look all too linear. It’s enough to say that you don’t always get what you want, but if you try sometimes, you get what you need.

An observer will be tempted to seek a common thread in all of this. It could be how innovative ideas are born, then wait for that “what-if” of lower costs to get to Earth’s orbit. This is not a syndrome unique to the space industry, the ability to wonder what might be, say if a material were stronger or lighter, it’s manufacturing cheaper. Our minds look ahead. What things we might do that day. The case for refueling in space, building power towers or private space stations, or advances from near-perfect fiber to life-saving medicines to scientific knowledge all depend on that cost metric. Yet, getting to know many of the innovators here over many years, the common thread seems elsewhere, in the perseverance of the champions of these possibilities before their time, without which the innovations wouldn’t be quite as ready when the affordable rides arrive.

Also see:

- The Case for Space Solar Power, 2014

- NASA Is Considering Fuel Depots in the Skies, Kenneth Chang, The New York Times 2011

- Space-Based Solar Power As an Opportunity for Strategic Security, 2007

Nice posting, Edgar. Lot’s of memories…!

LikeLike

Yes. The recent talk on SSP / SBSP by Dr. Coyote Smith was also just bought to my attention, at –> https://www.youtube.com/watch?v=fevs3Lg6HcA&t=3589s

LikeLike